If no menu

or buttons show

ensure you have

scripting enabled

Please give time

for menu to load

|

|

Duane's

Factory Visit - October 2004

Whilst this

feature is written up on the Rohrbaugh

Forum as a thread, the pictures are

very large to download plus, it seemed useful

to archive this as well, seeing as it is a

most informative look into the Rohrbaugh original

''inner sanctum''!

Note - this is of course the old Farmingdale

factory - the company has for most of 2005

been relocated to Deer Park, a bigger and

better facility. I hope we can have a new

factory tour from there eventually.

The text is reproduced as in the original................ |

|

Part

I

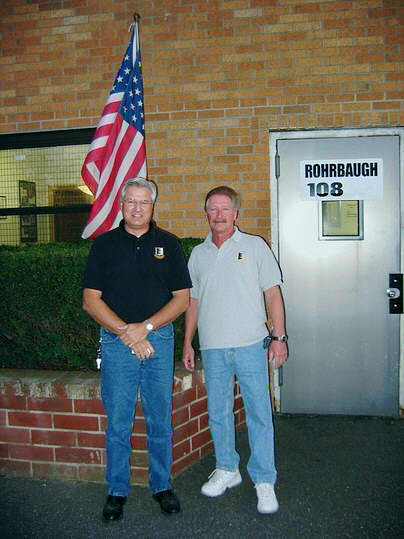

The Rohrbaugh Firearms

factory in Farmingdale, NY is just a 45 minute train

ride from Mid-town Manhattan.

I was lucky enough to have an invitation to visit on

October 6, 2004. Eric Rohrbaugh was waiting for me at

the train station in Farmingdale. I recognized his voice

- he was answering customer calls on his cell phone!

The factory is a nice, modern, high-security, but very

non-descript building in an industrial park.

Here is a picture of Eric and Karl in front of the building:

|

Inside the secure front

door is a small office. The desk you see is Maria's

desk - but she wasn't there. (No that is not a photo

of her on the left!).

On the walls are lots of R-9 promotional materials,

photos from the SHOT shows, etc. There are also photos

of Eric and Karl's family dating back several generations.

The Rohrbaugh crest used in their logo is an authentic

family crest in use for many generations - not just

a marketing gimmick.

|

| Eric also has a small

desk up front where he fields phone calls and works

on the computer. Note the reading material on screen!

|

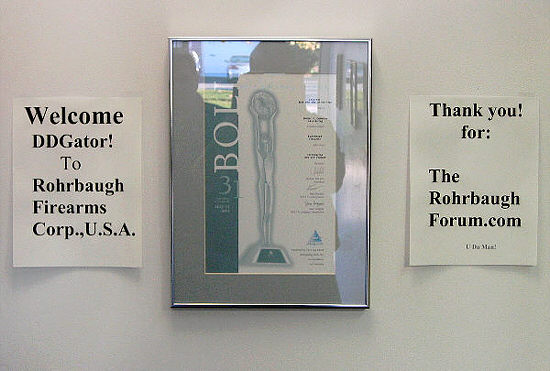

| Moving back farther

into the factory is a metal detector - and a nice welcome:

|

The hallway opens into

the largest room in the factory, which contains the

majority of the machining equipment. This is where the

slides, barrels and frames are made. I will probably

get some of this wrong, but here is the process as best

I can recall.

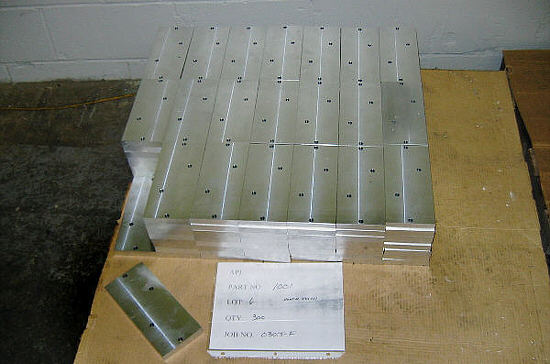

An R-9 starts as three blocks of metal (two stainless

steel, one aircraft aluminum) that are cut, shaved,

drilled, filed, polished, bead blasted and anodized

into a high quality handgun. The frames, of course,

are aircraft grade aluminum. Here is a picture of some

of the aluminum blocks.

Each block will become two frames. The holes you see

are cut by the metal supplier and are for mounting the

block inside the machine for processing.

|

|

Back to Top

|